Attention now turns to the rough uneven pile, which must be trimmed to a consistent height. Clipping the pile is usually performed in stages and in combination with several other techniques, often with several washings in between.

Opening up the pile requires the use of a long thin instrument pointed at one end.

The point catches the entangled tufts, forcing them to stand straight up ready for cutting or combing. The Hindi word “bhokai” summarizes the procedure.

“Berai”, another Hindi word meaning penciling or separating of the colors with a fine metal instrument, follows.

Finally the rug is combed vigorously to remove the excess yarn fibers.

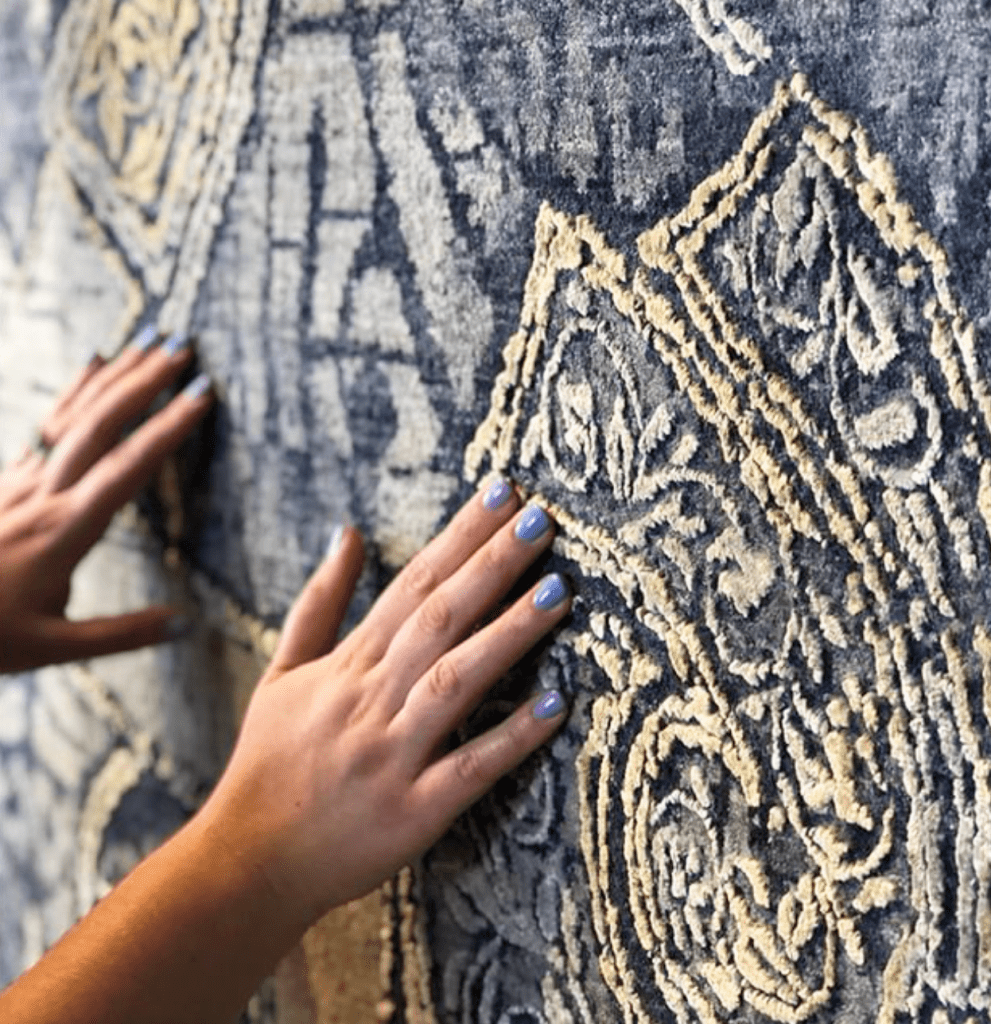

Perhaps now for the first time, after thousands of hours work, the true beauty of the rug is revealed.

As the final product begins to evolve, several finishing steps designed to “shape” the rug ensue.

Because cotton and wool are susceptible to shrinkage, the rugs must again be held under tension. The washing and natural drying of the rug causes the knots to tighten and thus alter the rugs size and shape.

The anchored hooks are inserted in close proximity to maintain an even strain all around, then tightened and re-tightened, over the course of several days, gradually stretching the rug into shape.

If performed correctly, the rug will lay completely flat on the floor, allowing any last adjustments to pattern, edge or pile.

At the top and bottom the last few knots are sewn together to prevent any fallout and the cotton ends are removed, in effect lengthening the fringe.

The warp strings at each end that form the fringes are finally tied, usually an indication that the rug is close to completion. Like the weaving of the knots, the work is meticulous. Again, slender nimble fingers are the ideal criteria, so women are often employed, sitting side by side.

The initial inspection of the rug may reveal the need to comb out, clip or open the pile further. If the buyer has requested a specific attribute, the rug may need to be aged or re-washed.

Before exportation however, a more formal inspection is required. In order to meet the exacting standards of the buyer, the rug is checked for quality, weave and finish. Attaching the seal symbolizes approval. Paperwork matching the rug’s number for customs and export purposes is filled out. Finished rugs are finally packed and marked for shipment to destinations across the globe.

It could be said, that handmade rugs are themselves interwoven into the very fabric of society in India, and like the sacred river Ganges, they play a profound role in everyday life.

They are both symbols of India’s age long culture and civilization, ever changing and yet ever the same.